The Oring is a torus, or doughnutshaped object, generally made from an elastomer that seals when compressed or deformed in a gland The huge popularity of the Oring seal dates back to 1939, when Niels A Christensen was granted a patent for its designJuly 15 , 17 Parker's ULTRA FF156 Solves Long Time Industry Challenge Providing Excellent Compression Set Resistance with Broad Chemical Compatibility April 03 , 17 Parker's ORing Division Changes Name to ORing & Engineered SealsParker's Oring Face Seal (ORFS) Tube Fittings and Adapters, SealLok, meet or exceed the requirements of both SAE J1453 and ISO and have international acceptance Oring face seal fittings offer zero clearance, resistance to over torque and vibration resistance making it an ideal reusable hydraulic fitting solution across many markets

What Is An O Ring Introduction To O Rings Satori Seal

O ring seal challenger

O ring seal challenger-ORing Materials for Oil and Gas Industry Harsh Environments from Experts We are experienced with the demanding applications found in the oil and gas industry Selecting the best material or seal design can increase service life and predictability,Extensive Inventory Global ORing and Seal is a major stocking distributor of ORings, ORing Cord Stock, ORing Assortment & Splice Kits, Spliced and HotVulcanized ORings, Oil Seals, Hydraulic and Pneumatic Seals, and other sealing products We carry one of the largest inventories in North America in our 52,000 sq ft distribution facility

How To Properly Choose Commercially Available O Ring Cross Sections Performance Seals Inc

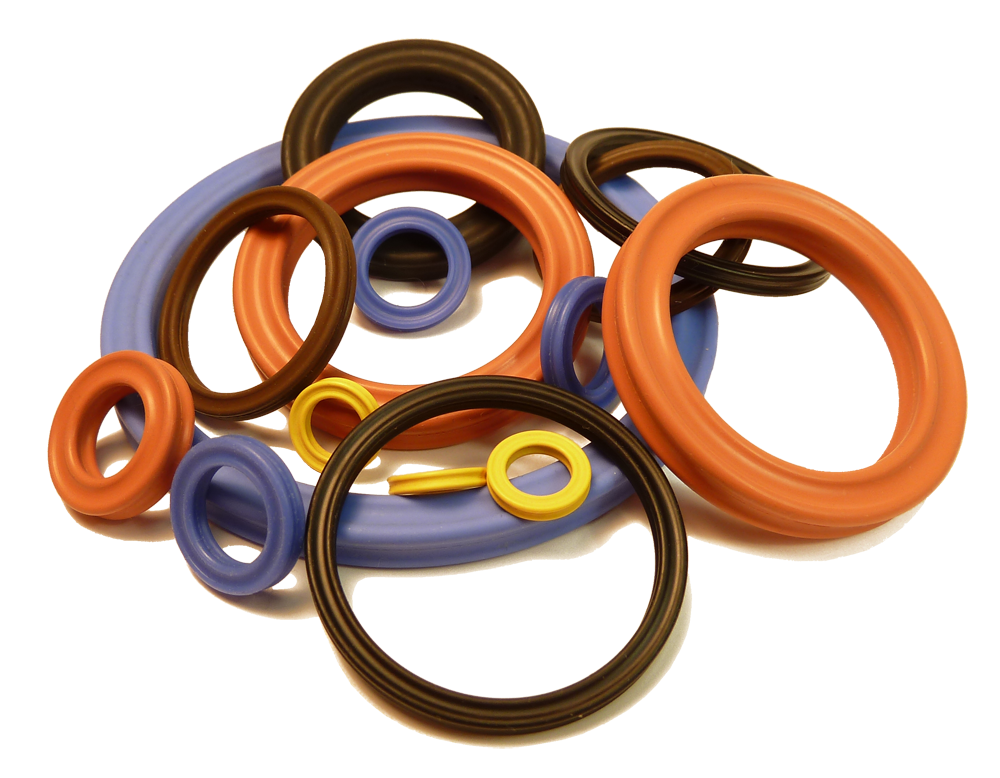

Endless ORings with a circular crosssection ORings are among the sealing classics par excellence Primarily used for static sealing of inactive machinery components against liquids and gases Special solutions and special forms from Freudenberg Sealing Technologies are also suitable as dynamic sealing elements, eg as piston or rod seals in the hydraulic systemNBR ORing Seals research categorizes SWOT Analysis of the global NBR ORing Seals market through breakdown data by manufacturers, region, type and application, also analyzes the market status, market share, growth rate, future trends, market drivers, opportunities and challenges, risks and entry barriers, sales channels, distributors and Porter's Five Forces Analysis of NBR ORing SealsPushing the Boundaries of Seal Design for 50 Years Over the last 50 years, Apple Rubber has pushed the boundaries of rubber seal design As a global innovator for industries ranging from aerospace to medical and everything in between, we're solving the world's toughest sealing challenges, one oring at a time

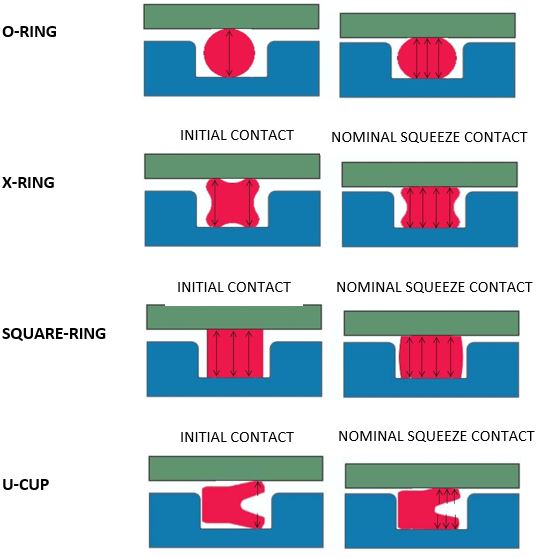

Welcome to our Oring Seal Design section This Oring seal design section will give you step by step instructions on how to design a seal or rubber part for your application Consider this a rubber guide or Oring guide in helping you find the exact rubber material and size you needSquare Ring Seal Chart SquareRings and Rubber Washers can be used in basic cost sensitive applications Square Rings and Rubber Washers can be molded, machined, or cut cost effectively depending on the size, material, and quantity Consider replacing SquareRings with ORings or XRings that often provide greater performance for the same or Ultimately, the Oring material shears and flows into the socalled extrusion gap, and the seal fails Dynamic applications can hasten seal extrusion But even in static applications, high pressure can stretch assembly bolts and open the extrusion gap sufficiently to permit leakage

They are available in metric and standard sizesFind Craftsman Washing Machine Gasket & Seal ORing Repair Parts at RepairCliniccom Repair your Craftsman Washing Machine Gasket & Seal ORing for less Fast, same day shipping 365 day right part guaranteed return policy Like an Oring, the Xring is a compression seal When initial squeeze is applied there are two solid bands of the crosssection in compression The Xring provides a more stable crosssection than the Oring, therefore it is recommended for those long stroke applications, or where a wider foot print seal is a benefit SquareRing

What Is An O Ring Seal Fundamentals Limitations Of Use

All Sae O Ring Face Seal Fittings Orfs Adapters Conform To The Sae J1453 Specification Order Today From The Fluid Connection Specialtist

The Oring is used for sealing straight thread tube fittings in a boss A boss is a cylindrical projection on a casting or forging The end of that projection is machined to provide a flat, smooth surface for sealing Straight threads used with an Oring provide a better sealORing Seals McMasterCarr Choose from our selection of Oring seals, including oilresistant BunaN Orings, oilresistant BunaN backup rings, and more In stock and ready to shipSeal & Design is a worldclass seal & gasket manufacturer and a name you can trust for gasket, seal and oring solutions Technical sealing has been defined by DIN Standards as follows • Static Seal – The sealing action created between two mating surfaces with no leakage of liquid or minimal diffusion of gas

O Ring And Seal Design Considerations Today S Medical Developments

Oring Ehandbook

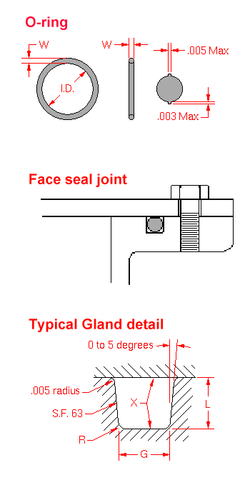

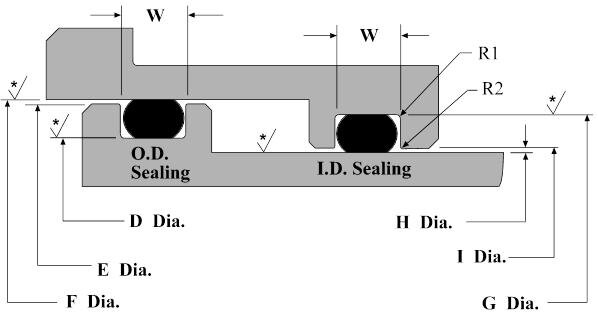

The oring gland design is very simple for face seals Simply cut out a circular groove into one of the plates and leave the other plate completely flat, the groove will have a square/trapezoidal cross section and the dimensions are conveniently already calculated and laid out in tables in the Parker Oring HandbookORings are used in a variety of fields they are either used as sealing elements or as energizing elements for hydraulic slipper seals and wipers Thus, the ORing is basically used in every field of industry including aerospace, automotive or general engineering Your Advantages Today, the ORing is the most widely used seal because of its inexpensive production methods and its ease ofORing Seal MS Parker Seal Black Rubber Lot of 2 $800 Was $1000 Free shipping or Best Offer Watch 10x Kapco Rubber ORing Intl' Seal 2" DIA M259/1036

O Ring Seal Hydrant Pit Valve Pvmy1000m3 Meggitt Z032ea Airportcomponents Com

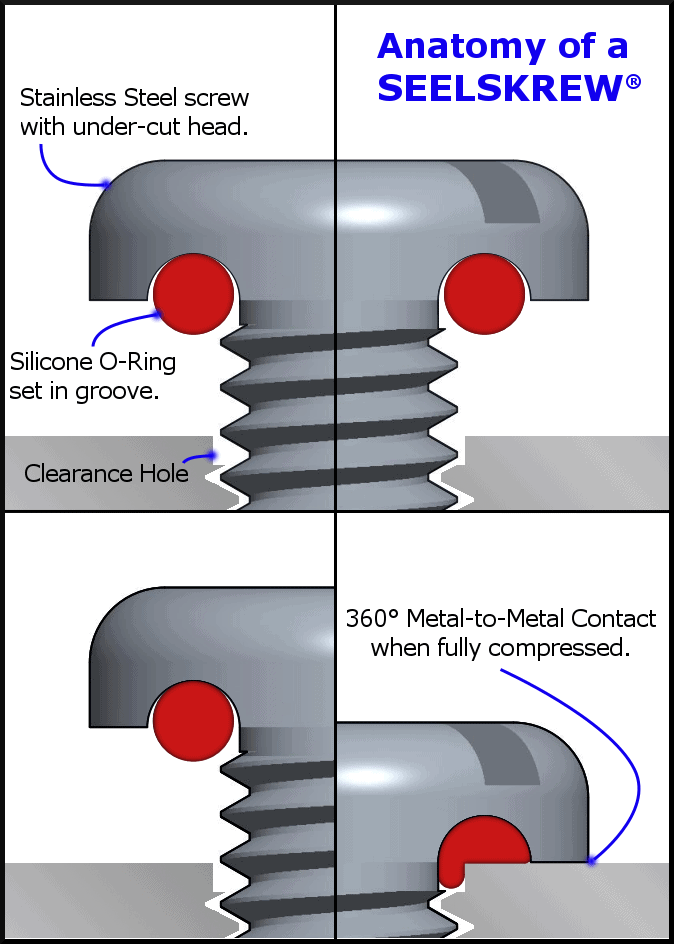

Anatomy Of An O Ring Screw Apm Hexseal Corporation

Seals and ORings Parker, the global leader in motion and control technologies, develops and manufactures innovative sealing solutions to meet the challenges ofDANCO Large ORing Assortment (45Piece) (9) Model# 105 DANCO #8 ORing (10Pack) (9) Model# DANCO #18 ORing (10Pack) (17) Model# ORing Seal Kit for Kitchen Faucets in White (118) Model# KGP304 DANCO #11 ORing (10Pack) (5) Model# DANCO #9 ORing (10Pack) (9) Model# DANCO #12 ORing (10Pack) (4) ModelSealing O Ring Kit, 270 Pcs ORing High Temperature Resistant Sealing BunaN Rubber Ring Assortment Kit for Industrial and Pneumatic YOOJIA 10Pcs Silicone Sealing ORings Gaskets for 45/52cm Vacuum Bottle Cover Stopper Thermal Cup Lid White 18 inches

500pcs Black Nitrile Rubber 1 5mm Thickness O Ring Seals 11 12 13 14 15 16 17 18 19 mm Od Nbr O Rings Sealing Gasket Washer O Ring Gasket Gasket Ringseal Ring Gasket Aliexpress

Rear Camshaft O Ring Seal For Mitsubishi Made In Japan Ships Fast Ebay

Metal Orings are an excellent lowcost metal seal with a proven history Static sealing all metal Oring seal made from hollow alloy tubing Available in several styles and compression loads for ease of design For temperatures from cryogenic to 1800F For pressures up to 60,000 psiORing Seal AS Kapco/Valtec Black Rubber Lot of 6 $719 Was Previous Price $9 Free shipping or Best OfferOring failure is often caused by a combination of factors including improper installation, allowing for too much or too little compression in the gland design, inadequate lubrication, abrasion, or using an Oring seal that is the incorrect size or type of elastomer for your application

How To Use An O Ring In A Non Circular Groove Pattern

1

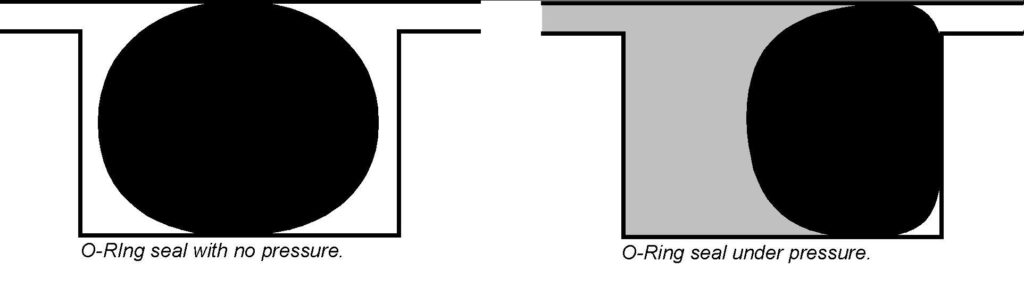

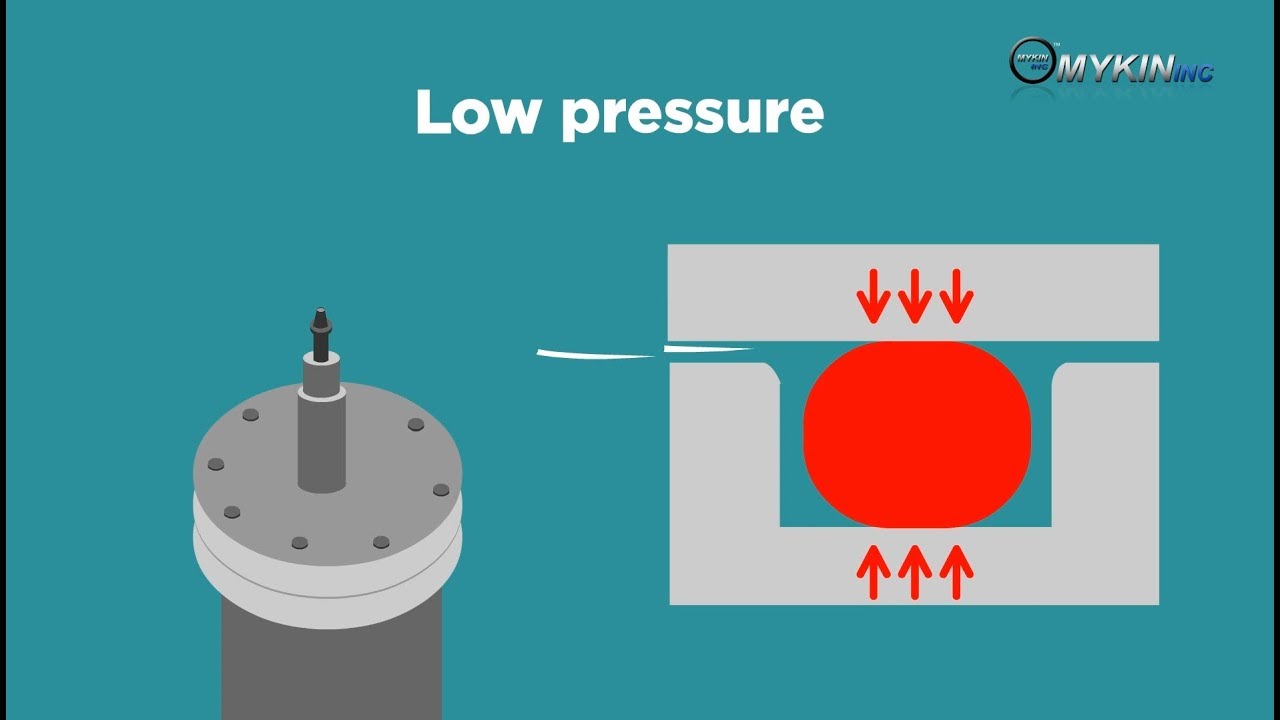

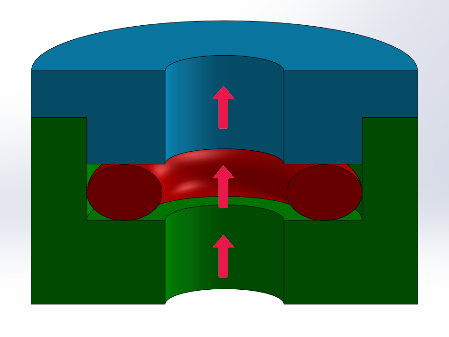

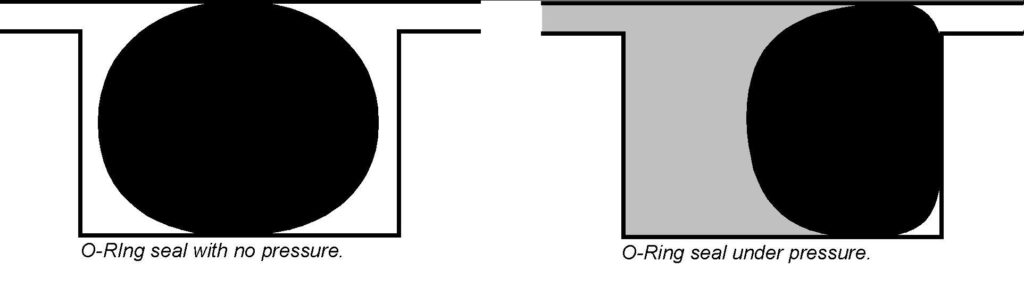

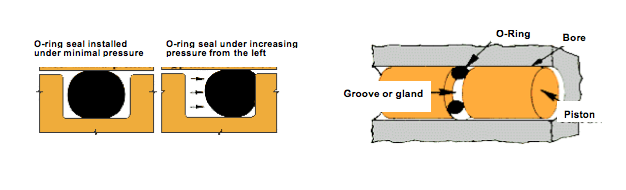

With flat edges on all four sides, these squareprofile Orings cover more surface than roundprofile Orings for a better seal in static applications, such as hose, pipe, and faucet connections SquareProfile HighTemperature Silicone ORings> Watch video Causes of elastomer Oring and seal failure Outgassing Plasma Degradation Visual indications A key marker is an even material loss on the surface of the part which is in contact with the plasma In some cases powdery residue on the seal surface and discolouration can also be observed depending on the filler type of the material The ORing sits in the middle of a gland when it's at rest, but as pressure begins to rise in the sealing system, the ORing shifts to the opposite side of the pressure Because the material is soft, the ORing is mechanically squeezed to plug the hole between the two mating hardware pieces Limitations of ORing use

China All Type Of Rubber O Ring Seal Completed Mold Various Color China Hydraulic Sealing Fixed Sealing

Rubber O Ring Seal Irrigation Direct

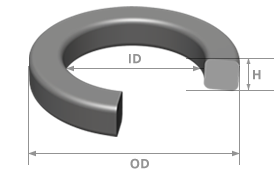

An ORing, also known as a packing, or a toric joint, is a gasket in the shape of a torus, or doughnut shape It is a loop of elastomer with a round crosssection, designed to be seated in a groove and/or compressed during assembly between two or more parts, creating a sealOring seals for aircrafts Aircraft orings and aerospace orings generally need to be highly chemically resistant, and able to operate within a wide range of temperatures and pressures in order to keep an aerospace craft's powertrain running cleanly, efficiently and smoothly Typical applications include fuel cap gaskets, fuel system oORing Tolerances for Cross Section and Inside Diameter The oring tolerances outlined in the charts below reference general purpose orings and xrings Find the right oring tolerance for your application and easily order online today from the world's largest oring inventory network

Tetraseal An Alternate Sealing Solution When An O Ring Isn T Working

Oversize Keg Lid Sealing O Ring

SKU FF1852T24S Category MALE ORING FACE SEAL X SAE BOSS ORING (FF1852) s ADAPTER, HOSE ADAPTER, HYDRAULIC HOSE ADAPTER, MALE ORING FACE SEAL X SAE BOSS ORING, PLUG, FF1852T24S Description Additional information Reviews (0) 1 1/4″ MALE ORING FACE SEAL X 1 1/2″ SAE BOSS ORING WeightORings 8,124 products Get durable BunaN and Viton Orings from Grainger to help tightly seal connections in a wide range of industrial applications BunaN rings with durometer 70 shore A can offer hood physical properties and provide excellent resistance to petroleum productsRequired ORing Information Sizing Must Use This Formula 2 (CS) ID = OD AS568 # or ORing Size (inch or metric) Cross Section ( thickness ) X Inside Diameter 2 (CS) ID = OD Temperature Requirements Compound or Material Being Sealed Operating Pressure

Seal Ring Eclipse Engineering Inc

O Ring Wikipedia

ORing Seals Orings are one of the simplest and most effective seals ever invented a loop of elastomer with an oshaped crosssection Orings are commonly made from viton, silicone, nitrile and neoprene;The Pressure Seals Oring size will be found in the first column next to the shaft diameter BACKUP RINGS (Design Chart 7) When you have a tendency for Orings to extrude between the sealing areas under pressure, there are three choices available to minimize this 1 A harder OringIn very basic terms, oring seals work by sitting in a groove or channel between two surfaces/components that are going to be mated or pushed together The oring, generally made of some form of elastomer, sits in the join between these two parts, and becomes compressed in order to help form a tight seal

What Is An O Ring And How Does It Work Youtube

How To Properly Choose Commercially Available O Ring Cross Sections Performance Seals Inc

An oring is one of the most common types of seals in the world ORings are used in a variety of applications in different industries around the world Because of its popularity, there is virtually an unlimited number of possible sizes of an oring Thus, the need for size standards which cover the most common sizes usedSeal assembly consists of an elastomer Oring and a gland An Oring is a circular crosssection ring molded from rubber (Figure 11) The gland — usually cut into metal or another rigid material — contains and supports the Oring (Figures 12 and 13) The combination of these two elements;1 Male or Plug the Oring groove is located on a plug which is inserted into the housing or cylinder (fig 123) 2 Female or Tube the Oring groove is located in the housing or cylinder and a tube is installed through the Oring lD (fig 124) Male or Plug Seal design is based on the following factors (refer to fig 123) Bore

Cg 124 Joints O Ring Seal Chemglass Life Sciences

O Ring Seal An Overview Sciencedirect Topics

Oring and gland — constitute the classic Oring seal assembly Groove BoreTborst oring seal vs ferule bite fittings tborst tubing reccomendations for use with oring fitting tborst installation of oring seal fitting tborst labor cost savings of oring seal fitting products hydraulic filters hydraulic tank accessoriesLepu john crane type 1 sealo ring design john crane type 1 sealo ring design made by Guangzhou Lepu Machinery CO, LTD promises strong durability and strong practicality for the market after our years of commitment to innovation and development of the product It is the fruit of our research and development and has been widely accepted for

Replacement Rubber Sealing Gasket O Ring Seal Washers 75mm X 68mm X 3 5mm New Walmart Com Walmart Com

Pacific Hoseflex O Rings Seal Rings Hammer Union Seals Pacific Hoseflex

How to Change out Tube Seals on your spark plugs, this is practically the same for every vehicleYou will needSocket Set, Screwdrivers, Rags, a razor blade,Double "O" ring seals have been used for many years to provide an aseptic seal for glass electrodes in stainless steel housings in fermenters This system is suitable for lower level hazards, provided that release of microorganisms is minimized and there are adequate disinfection procedures for dealing with leakages (Werner, 1992)

O Ring Seal High Res Stock Images Shutterstock

What Is An O Ring What Is An O Ring Seal Instrumentation Tools

Metric And Imperial O Ring Kits Hydraulic Megastore

Land Rover O Ring Oil Cooler Pipe

O Ring Seal An Overview Sciencedirect Topics

Viton O Ring Seal For Agilent Liners 6 3mm Od 10 Pc Pak Analytics Shop Com

Gasket Vs O Ring Differences And Common Applications

Oring Ehandbook

Seals Eastern End Cap O Ring Seal Design Guideline

Osk 1 Piece Pressure Washer Qd O Rings Seal Kit K1x6pw The O Ring Store Llc We Make Getting O Rings Easy

O Ring Seal Kit

O Ring Seals Aftermarket Caterpillar Parts Costex

Eai As568 O Ring Seal 219 Pack Of 10 Id 1 5 16 Cs 1 8 Buna N 70a Durometer 1 5 16 X1 9 16 X1 8 Nitrile Rubber Oring Amazon Com Industrial Scientific

Leading Provider Of O Rings Oil Seals And Related Sealing Products A Leading Provider Of O Rings Oil Seals And Sealing Related Products

O Ring Seal Simulation Subjected To Pressure Of A Fluid

Air Arms O Ring Seal Kit For S400 410 And S500 510 Caliber Specific Breech O Ring Sold Separate Air Arms

Dynamic O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

Briggs Stratton 6905 Seal O Ring Briggs Stratton Online Store

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

1

Nbr Cylinder Liner O Ring Seal 45x58x14mm Ay Dusty Proof Piston Seal Ring Nitrile Rubber Pneumatic Ring Cylinder Gasket Ring Gasket Rubber Ring Gasketsrubber Gasket Aliexpress

25r22x1v75 Rs Pro Rs Pro Fkm O Ring Seal 22mm Bore 24mm Outer Diameter 196 5638 Rs Components

279pcs 18 Sizes Rubber O Ring Assortment Kit Black O Ring Seal Gaskets Hydraulic Plumbing Gaskets Amazon Com Industrial Scientific

New 5 Pack 5 Diameter Rubber Gasket O Ring Seal U Channel Round Ebay

O Rings O Yeah How To Select Design And Install O Ring Seals Youtube

Square Ring Seal Size Chart Standard Square Ring Seal Size

1

O Ring Seal Centurion Eaton Sas Circular Metal Carbon

Seal Design O Ring Design O Ring Design Guide

How To Maintenance And Care Procedures For O Ring Seals Youtube

What Is An O Ring What Is An O Ring Seal Instrumentation Tools

Silicone O Rings Silicone Seals Silicone Gaskets

Selection Guide Standard Size Quad Ring Brand Seals And Quad Brand O Rings Seals Minnesota Rubber Plastics

0pcs 3mm Thickness O Ring Seals Gasket Nbr 30 31 32 33 34 35 36 37 38 39mm Od Nitrile Rubber O Rings Seal Washer Sealing Washer Sealing Gasketsrubber O Ring Aliexpress

Replacement Gasket O Rings Seals Healthy Human

Rs Pro Nitrile Rubber O Ring Seal 24 5mm Bore 30 5mm Outer Diameter Rs Components

O Ring Seal 6 5mm X 11 5mm X 2 2mm Caliper Seal

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

Oring Ehandbook

O Ring Lid Seal Midwest Supplies

O Rings Seal Products Products Nok Corporation

What Is An O Ring What Is An O Ring Seal Instrumentation Tools

What You Need To Know About Dynamic Seal Applications Hot Topics

Litorange Silicone 580pcs 45a Universal Black O Ring Sealing Gasket Washer Seal Assortment Set Better Than Rubber For Plumbing Automotive General Repair 15 Size With Case Amazon Com Industrial Scientific

Backup Rings Buy O Rings Seals Custom Molded Rubber Engineered Plastic All Seals

Quad Rings X Rings Supplier Rocket Seals Inc

Walfront Paint Sprayer O Ring Seal Rings Pump Repair Packing Kit Fits For Ultra 390 395 495 595 Walmart Com Walmart Com

What Is An O Ring Introduction To O Rings Satori Seal

X Ring Seals Quad Ring Seals Low Friction Seals Precision Associates Inc

O Ring Flange 6 Series

Buna O Ring O Ring In Houston And Minneapolis Dichtomatik

D Ring Seals Rubber D Rings Precision Polymer Engineering

Ocgig 225 Pcs O Ring 18 Sizes Rubber Sealing Gasket Rings Washer Seal Assortment Set For Plumbing Automotive General Repair Amazon Com

Centering Ring Seal Assembly

O Ring Seal Oring Kit For Hitachi Nra2 Nailer Nail Gun Walmart Com Walmart Com

Formula O Ring Seals 2 99 R1 Rx Ro One Epic Bleed Solutions

Gasket Vs O Ring Differences And Common Applications

Ashutosh Yellow Black High Performance Metal Rubber O Ring Seal Id

Vacuum Extractor Replacement Viton O Ring Seal Gilson Co

Would Slippery O Rings Or Seals Improve Your Product Performance

O Ring Seal Advancap Greene Tweed Elastomeric Piston

O Ring Wikipedia

Rs Pro Nitrile Rubber O Ring Seal 121mm Bore 124mm Outer Diameter Rs Components

Automotive Applications For O Ring Seal Hutchinson

O Rings And Seals Flat Rubber Seal Ring O Ring Seal High Temperature O Rings Fuel O Rings Freudenberg Fst

Amass India Rubber O Ring Seal Rs 12 Piece Amass India Id

How Does An O Ring Seal Work

D Ring Seals For Dynamic Applications Fda 3a Compliant Barnwell

O Ring Seal For Standard Sae An O Ring Ports Buna Pegasus Auto Racing Supplies

Rs Pro Nitrile Rubber O Ringo Ring 39 5mm Bore 45 5mm Outer Diameter Rs Components

3

Elastomer O Ring Seals Vs Omniseal Spring Energized Seals A Comparison

How To Chose O Ring Material For Your Fluid Sealing Applications Phelps Industrial Products

5 9l 6 7l Dodge Cummins Mprop O Ring Seal Kit 03 18

What Are The Different Types Of O Rings Blog Kb Delta

Seal Design O Ring Design O Ring Design Guide

Pall Filter Housing O Ring Seal Pdc800s

Black Rubber O Ring Seal Size 3 Inch Shape Round Id

Types Of O Ring Applications

O Ring Lusida Rubber Products

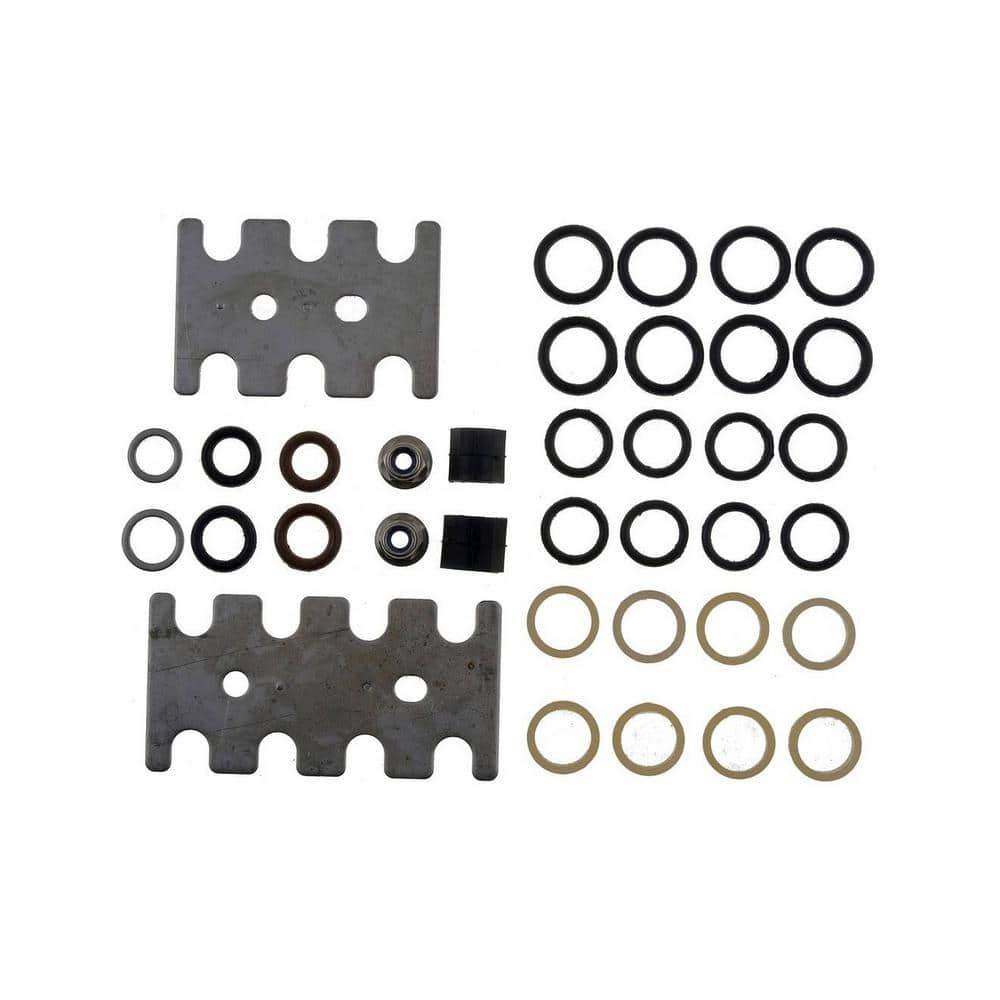

Fuel Injector O Ring Seal Kit The Home Depot

Buna O Ring O Ring In Houston And Minneapolis Dichtomatik

0 件のコメント:

コメントを投稿